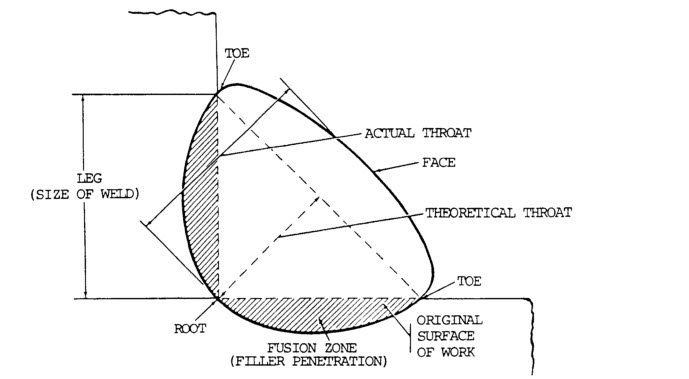

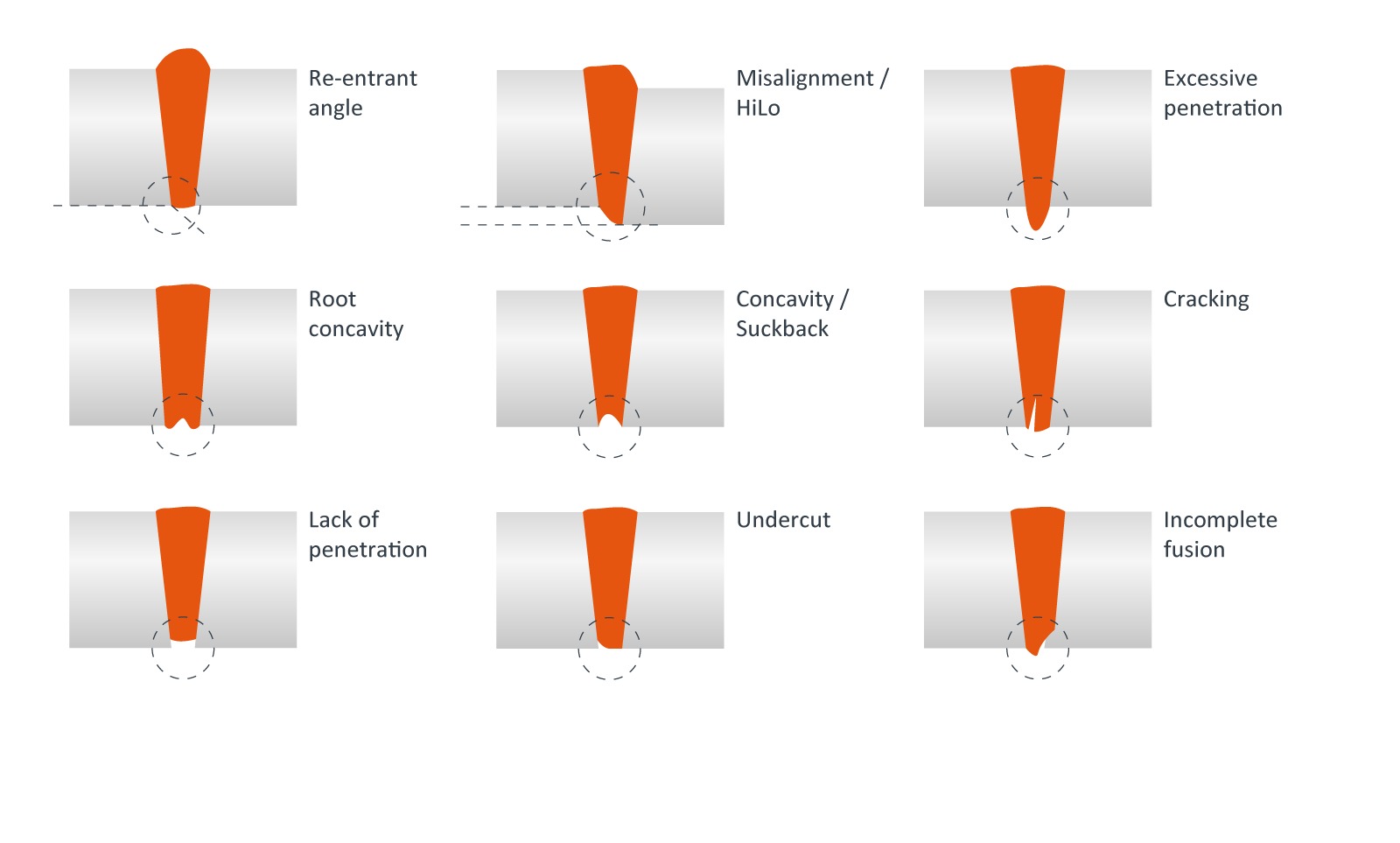

Lack Of Inter Run Fusion. Cacat Las yang tidak fusi di antar layer atau pass weld metal, cacat ini terjadi dapat dikarenakan arus yang terlalu rendah, sudut elektroda yang tidak tepat dan pengelasan terlalu cepat. The corrosion performance of welds in duplex stainless steels is crucial to qualification of weld procedures. This paper describes lack-of-fusion-like flaws which can be formed at weld toes particularly in pipe butt welds in duplex grades of stainless steel. The lack of fusion is a planar defect. It may appear at the edge of the parent metal or between runs. The lack of fusion between the parent metal and the weld metal shows a flat face. The lack of inter-run fusion, however, shows an irregular shape. A single straight line on the graph in the root area was classed as Lack of Root Fusion. Two parallel straight lines on the graph were classed as Lack of Penetration (Incomplete Penetration in US terminology). One is classed as a discontinuity and is acceptable and one is classed as a defect and is not acceptable.

Lack Of Root Fusion In Welding

Mig Welding Lack Of Root Fusion

Lack Of Root Fusion Radiograph

at the danger you may lough on me when I am asking the following.

Can anyone of you kindly explain to me the difference between 'Penetration' and 'Fusion' ?

Due to the very interesting topic of Shane Feder just shortly ago and the excellent explanations of Gerald 'CWI555' I guess that I have misunderstood and further made something wrong when I have discussed sometimes to fellows in the past, and have used the term 'depth of penetration' for expressing the depth the weld metal has 'fused' the base-material.

From the explanations of Gerald I mean to have understood that the 'Depth of Penetration'(?) is not equal the 'Depth of Fusion'(?) in the US-Standardization. Is that true or have I misunderstood something totally wrong.

Background of the question is - of course - the topic of Shane but also the fact that within the German/European Standardization (at least as far I know) is no difference to find between 'fusion' or 'penetration'. In Germany we use the term 'Einbrand' what approximately means how 'deep' the arc has 'penetrated' into the base metal and which is indirectly a 'gauge' for where the fusion line can be located.

Thanks in advance to those one who will kindly show me the way!

Regards,

Stephan